History

The origins of OMP srl (acronym for mechanical and precision engineering workshop) date back to 1965. At first, the company dealt with general maintenance and mechanical construction. Over the years OMP developed and branched off into various activities, for example mechanical maintenance and services for chemical industries, servicing of rotating machines intended for power generation, planning and realization of special machines and equipment for the aerospace sector.

OMP is part of a Group of 8 companies specialized in various industrial sectors, that on the whole employs a staff of about 190 people, with a global revenue of over € 35.000.000, of which over 20% is directed towards exportation on a European and worldwide level. Most of the Group’s manufactured goods are produced at OMP.

PROCESSING/MANUFACTURING

- - Engineering and realization of special machines

- - Mechanical manufacturing

- - Metal carpentry and special welding processes

- - Electric kiln for thermal treatments and hot assemblies

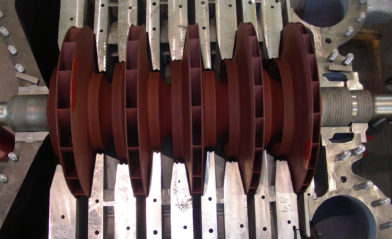

- - Servicing of machines and turbomachines

- - Servicing of industrial apparatuses

- - Reverse engineering

- - Dynamic balancing, vibrational analyses, laser alignments

- - Servicing of safety valves and relative calibration

- - Authorized workshop for maintenance of valves (PHONIX, DESCOTE, PARCOL, AUMA)

- - Various controls: three-dimensional with DEA machine, penetrating liquids, ultrasounds, roughness

OMP designs, manufactures and sells the following products worldwide, with the “OFFICINA 2000 milling machines” brand:

– Dosage systems, transport and injection of reagents for treatment of fumes

– Milling machines for grinding/micronizing of several materials

Resources

OMP boasts a workshop where modern and performing numerically controlled large machinery is installed, thanks to which the company employs around 50 people including engineers, technicians and specialized operators, who can carry out multiple manufacturing requests from the clients. Moreover, OMP integrates itself and creates synergies with its subsidiaries, thereby guaranteeing comprehensive and technologically innovative solutions, deriving from the collaboration between the human and instrumental resources that the whole Group relies on. The end result is a total service that satisfies client needs promptly through high level services.

- Innovative technological solutions

- Timely responses

- Full Service and high-level performance

Certifications

UNI EN ISO 9001_2015 (Quality System)

CNC machining, design and manufacturing of industrial machines: pumps, valves, maintenance of rotors

UNI ISO 14001_2015 (Environmental Management System)

CNC machining, design and manufacturing of industrial machines: pumps, valves, maintenance of rotors

ISO 45001_2018 (Security System)

CNC machining, design and manufacturing of industrial machines: pumps, valves, maintenance of rotors

Italian Institute of welding

qualified welding

PHONIX ARMATUREN WERKE

revision of valves, official maintainer

DESCOTE

revision of valves, official maintainer

PARCOL

revision of valves, official maintainer

AUMA

revision of actuators, official maintainer

OMP's Policy

Customer satisfaction and efficiency of our industrial processes, complying with all the HSE regulations

Download pdf

100% GREEN ENERGY

OMP uses 100% renewable energy

Partners

We are integrated with the following companies that are part of the Group:

TECNO Srl

Engineering for the mechanical industry, machine construction.

Rosignano Solvay (LI)

Officina 2000 Srl

Mechanical maintenance, maintenance of industrial facilities, plastic materials.

Railway maintenance and testing.

Rosignano Solvay (LI)

PR.ENER.CA. CERESIO Srl

Building and commissioning of energy production plant.

Rosignano Solvay (LI)

Gyromarine Srl

Design and manufacturing on naval gyroscopes for stabilization.

Rosignano Solvay (LI)

Contacts

SUBSIDIARIES

Australia (Perth)China (Beijing, Hong Kong)

France (Chambéry)

Italy (Grosseto, Pisa)

Poland (Krakow)